Lumax LX-3007-10 1/4"-28 Taper Thread (SAE-LT) Straight 0.54" Long Grease Fitting, (Pack of 10), the Ball Check Prevents Dust and Dirt Contamination

En stock

0.20 kg

Sí

Nuevo

Amazon

- PRECISION ENGINEERED FOR HEAVY-DUTY USE: LX-3007 straight grease fittings are manufactured from high-grade materials, providing superior strength and durability for demanding lubrication tasks in trucks, automotive, agricultural, industrial, marine, and construction equipment.

- DURABLE & LONG-LASTING: Fully hardened fittings with heavier wall thickness resist wear from constant use, ensuring extended service life under heavy-duty conditions.

- CONTAMINATION PROTECTION: Built-in ball check in the head prevents dirt, grit, and debris from entering the fitting, maintaining clean and efficient grease flow.

- CORROSION RESISTANT FINISH: Zinc plated with yellow passivated coating for maximum protection against rust and corrosion, maintaining performance over time.

- TESTED & RELIABLE: Individually inspected and batch-tested to 5,000 PSI (344 Bar); features stress-relieved, tempered carbon steel springs and thread-rolled taper threads for superior strength and reliability compared to cut threads.

IMPORT EASILY

By purchasing this product you can deduct VAT with your RUT number

U$S 25 OFF pagando con tarjetas Banco Pichincha

Compra protegida

Disfruta de una experiencia de compra segura y confiable

¿Cómo comprar?

Información de Aduanas Ecuador

En Tiendamia puedes hacer tus compras a través de la categoría B (4x4) y la categoría C. No tendrás que hacer trámites de aduana. Hacemos todo por ti.

- El 4x4 (o categoría B)

- a. No paga impuestos ecuatorianos.

- b. Tienes una cantidad ilimitada de órdenes en el régimen 4x4 siempre que cada una de estas esté dentro del peso máximo permitido (hasta 4 kg) y no superen los $400, además de cumplir con el cupo anual por persona.

- c. El cupo anual máximo es de $1.600 al año para compras en el exterior a través del régimen 4x4. El cupo anual se limitan a una cédula pero no a tu usuario de Tiendamia.

- d. Se puede comprar una gran variedad de productos dentro de esta categoría siempre y cuando cumplan con el 4x4 y no sean para fines comerciales, por esa razón, se puede comprar máximo 3 productos iguales o similares de la misma categoría. Por ejemplo, puedes comprar hasta 3 perfumes, hasta 3 relojes y hasta 3 pares de zapatos, si te excedes de esta cantidad tu orden puede tener cargos extra por parte de la aduana.

- Las tablets, laptops y celulares se pueden comprar a través de la Categoría C.

- a. Esta categoría sí paga impuestos (IVA + Fodinfa)

- b. Solo se puede comprar un celular nuevo al año, no se admiten refabricados, usados u “open box.”

![]() Garantía de entrega

Garantía de entrega

Con Tiendamia todas tus compras cuentan con Garantía de Entrega o devolución total de tu dinero.

Compras 100% seguras y garantizadas, para que pidas lo que sueñas y lo recibas del mundo a tu puerta.

¿Cómo solicitar una devolución?

Para solicitar una devolución, el cliente debe realizarlo a través de su cuenta de Tiendamia. Este proceso está sujeto a la aprobación del departamento de Devoluciones (lo cual puede demorar de 48hs a 72hs hábiles). En caso de no tener la opción en la web, el cliente debe contactarse con Atención al Cliente para iniciar la solicitud.

Los productos sin devolución son:

- Los productos que tienen un tiempo de entrega mayor a 20 días hábiles.

- Productos que por su naturaleza no admiten devolución en EE.UU. o China y, por lo tanto, Tiendamia no puede ofrecer la devolución al cliente. Ejemplos: perfumes, cremas y medicamentos.

Tarjetas de Débito y Crédito

Visa

Mastercard

American Express

Dinners

Discover

Alias

Pagos a través de PayPal

Compra procesada en dólares con dinero en cuenta o tarjetas internacionales.

PayPal

Conoce más detalles

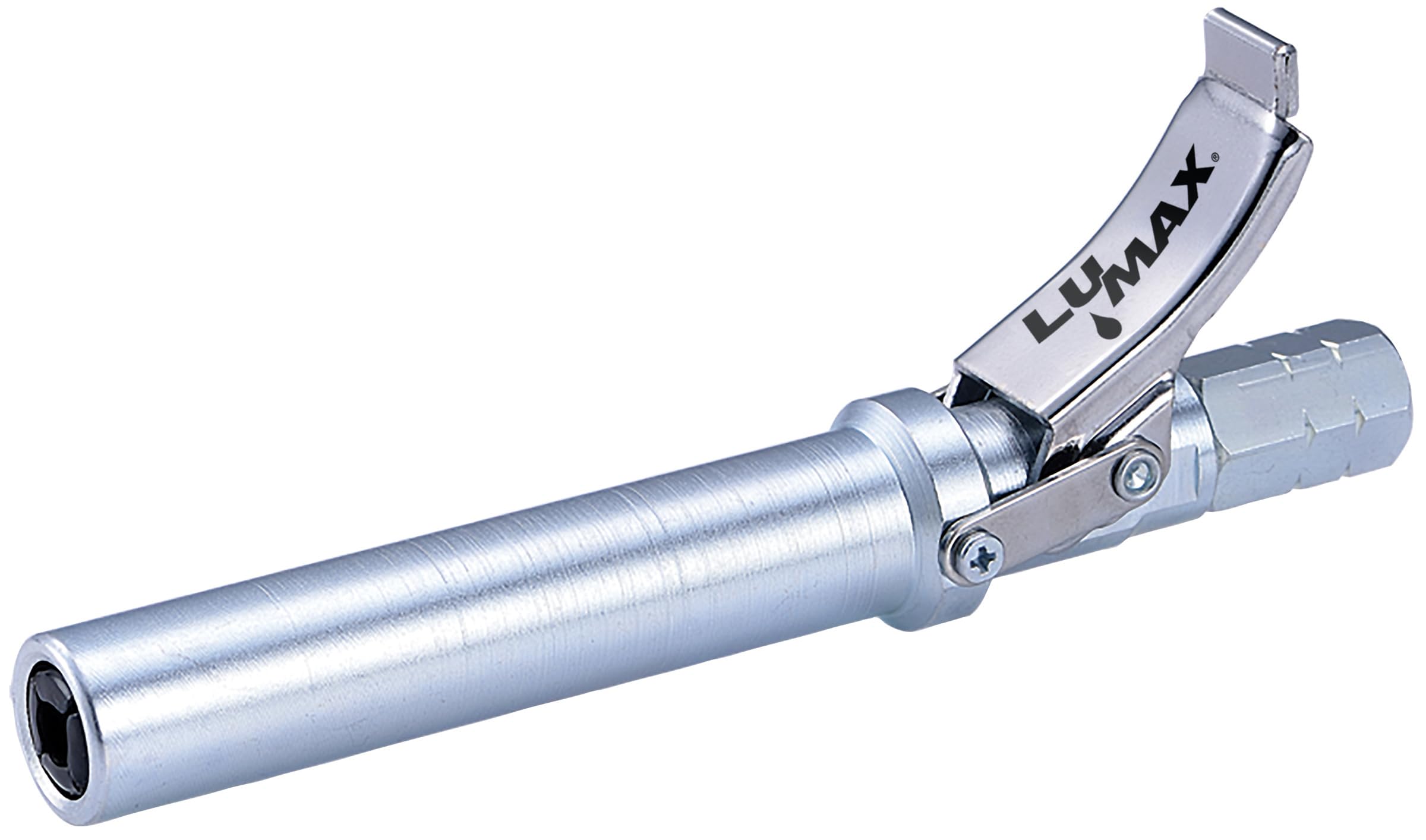

This a 1/4 inches-28 taper thread (SAE-LT), straight, 0. 54 inches grease fitting. It is used on most auto vehicles and on industrial equipment. SAE-LT threads conforms to society of automotive engineer’s lubrication thread specification. The ball check prevents dust and dirt contamination. These fittings have a ball check in the head to prevent dirt and grit from getting into the fitting, heavier wall thickness for extra strength, are zinc plated with a yellow passivated finish for maximum protection against corrosion, and have a stress relieved and tempered carbon steel spring. Every fitting is individually inspected, and batch tested to 5, 000 PSI and are designed to meet the demanding requirements of most automotive, agricultural, industrial, marine, truck, federal and construction equipment needs. Lumax's mission is to provide professionals and consumers with innovative and high-quality products to get the job done right. Product development at Lumax goes beyond the physical product, to a deeper understanding of the end-users' needs. Engineered with the "user-in-mind, " Lumax products are built to the highest standards and incorporate many unique features that make work easier, faster and cost-effective. We have a passion for the design process. We listen to our customers and their ever-expanding requirements. Our unique products lead the field in design, quality, and performance.

.svg)