SKU/Artículo: AMZ-B0FQ9W5TT5

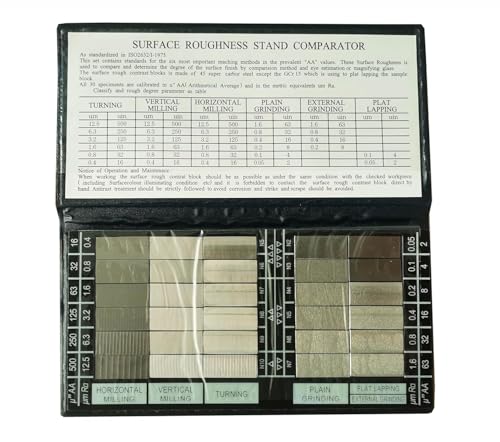

Surface Roughness Gauges Set 30 Specimens Surface Finish Comparator Set for Comparing and Determining The Degree of The Surface Finish Ra0.05-12.5um

En stock

0.67 kg

Sí

Nuevo

Amazon

- These Surface Roughness is used to compare and determine the degree of the surface finish by comparision method and eye estimation or magnifying glass.

- This set contains standards for the six most important maching methods in the prevalent "AA" values. These surface rouhness is used to compare and determine the degree of the surface finish by comparision method and eye estimation or magnifying glass.

- As standardized in ISO2632/I-1975; Specifications meet S.A.E. and military specifications for visual and tactile inspection.

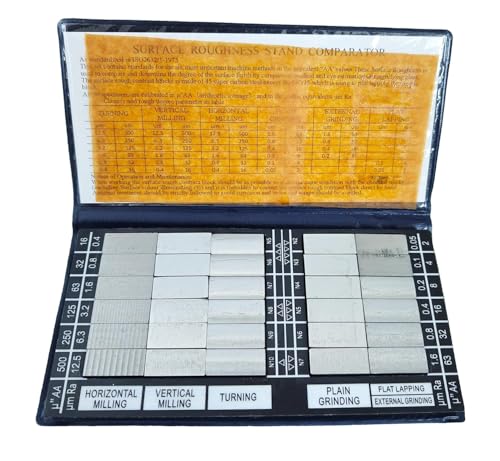

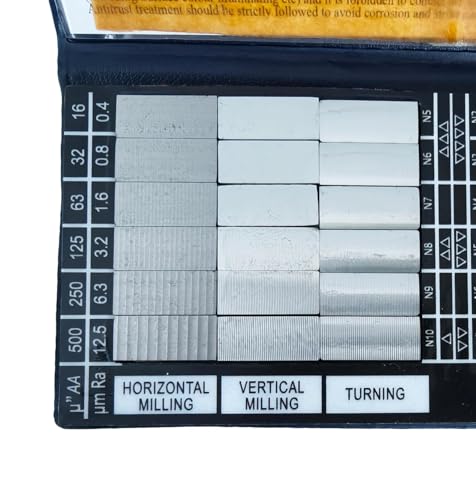

- All 30 specimens are calibrated in u" AA(Arithmetical Average) and in the metric eqaivalens um Ra.

- The surface rough contrast blocks is made of 45 super Carbon Steel except the GCr 15 which is using to plat lapping the sample block.

IMPORT EASILY

By purchasing this product you can deduct VAT with your RUT number

Conoce más detalles

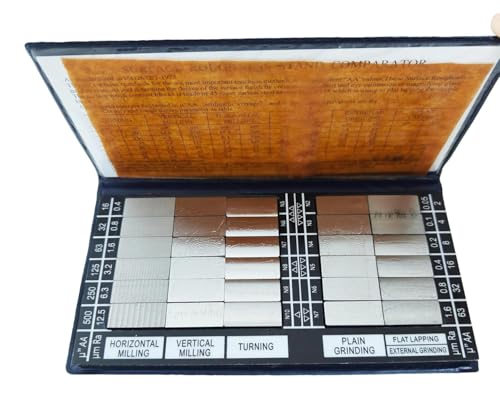

Features: These Surface Roughness is used to compare and determine the degree of the surface finish by comparision method and eye estimation or magnifying glass. This set contains standards for the six most important maching methods in the prevalent "AA" values. These surface rouhness is used to compare and determine the degree of the surface finish by comparision method and eye estimation or magnifying glass. As standardized in ISO2632/I-1975; Specifications meet S.A.E. and military specifications for visual and tactile inspection. All 30 specimens are calibrated in u" AA(Arithmetical Average) and in the metric eqaivalens um Ra. The surface rough contrast blocks is made of 45 super Carbon Steel except the GCr 15 which is using to plat lapping the sample block. Specifications: This kit has 30 specimens, each 7/8“×3/8” and contains: 3 Specimen Flat Grinding - 2, 4, and 8μ“ AA; 3 Specimen Reaming - 16, 32, and 63μ” AA; 6 Specimen Grinding - 2, 4, 8, 16, 32, and 63μ“ AA; 6 Specimen Horizontal Milling - 16 , 32, 32, 63, 125, 250, and 500μ” AA; 6 Specimen Vertical Milling - 16, 32, 63, 125, 250 and 500μ“ AA; 6 Specimen Turning - 16, 32, 63, 125, 250 and 500μ” AA.